What is the backbone of the manufacturing space? Great question!

CNC manufacturing of course!

That car you drive, the phone you use, the aircraft taking you to new places, and the life-saving medical equipment owes its thanks to CNC manufacturing.

CNC machining doesn’t just make parts; it builds the future. From aerospace and healthcare this process turns raw materials into the essential components that power everything in our modern world. But here’s the catch. It’s tight tolerances and speed make it the backbone of manufacturing.

In this article, we’ll cover everything you need to know—from what CNC machining is to its history, types, applications, and features. Let’s dive in!

What Is CNC Machining?

CNC stands for Computer Numerical Control, a manufacturing process where computer software is used to control machinery and tools. These tools include lathes, mills, grinders, and routers, which can shape, cut, and drill materials with exceptional precision. Unlike manual machining, CNC machining operates autonomously once the program is set, ensuring consistent results across multiple runs.

The CNC process starts with a digital design, often created in CAD (Computer-Aided Design) software. This design is translated into a machine-readable format using CAM (Computer-Aided Manufacturing) software, which generates instructions to guide the tool’s movement.

Learn More about what CNC Machining is →

A Brief History of CNC Machining

The roots trace back to the late 1940s, when early numerical control (NC) systems were developed. These systems used punch cards to guide machine tools, allowing for greater precision than manual controls.

In the 1950s, computers were integrated into these systems, marking the birth. Early CNC machines were limited in capability but quickly evolved with advancements in computing power and programming languages.

By the 1970s and 1980s, CNC machining became widespread in industries like aerospace, automotive, and defense. Today, it’s an essential technology in nearly every manufacturing sector, from medical devices to consumer electronics.

Types of CNC Machining

CNC machining encompasses several types of processes, each suited for different tasks. Here are the most common:

CNC Milling

Milling is one of the most versatile CNC processes. It involves rotating multi-point cutting tools to remove material from a workpiece, shaping it into the desired form. CNC mills are widely used to create complex parts with intricate designs, such as engine components and custom molds.

CNC Lathes

Lathes are ideal for producing cylindrical or symmetrical parts. In this process, the workpiece rotates while stationary cutting tools shape it by removing material. CNC lathes are commonly used for manufacturing shafts, bushings, and threaded fasteners.

5-Axis Machining

5-axis machines are the pinnacle of CNC technology, capable of moving tools or the workpiece across five different axes simultaneously. This flexibility allows for the production of intricate geometries and complex designs in a single operation, saving time and improving accuracy.

Explore more about 5-Axis CNC Machining →

Additional CNC Machining Processes

Other CNC processes include waterjet cutting, laser cutting, and plasma cutting. Each of these techniques has its own advantages, depending on the material and application.

Benefits

CNC machining offers numerous benefits that make it indispensable in modern manufacturing:

- Unmatched Precision: Achieves tolerances as tight as ±0.001 inches, ensuring parts meet strict quality standards.

- High Efficiency: Automation reduces production time and labor costs while maximizing output.

- Consistency: The ability to replicate parts with identical specifications ensures reliability in mass production.

- Flexibility: CNC machines can work with a variety of materials, including metals, plastics, wood, and composites.

- Cost-Effectiveness: While the initial investment may be high, CNC machining reduces long-term costs by minimizing waste and errors.

Applications

CNC machining plays a crucial role in industries worldwide. Here are some of its key applications:

- Aerospace: Manufacturing high-precision components for aircraft, satellites, and rockets.

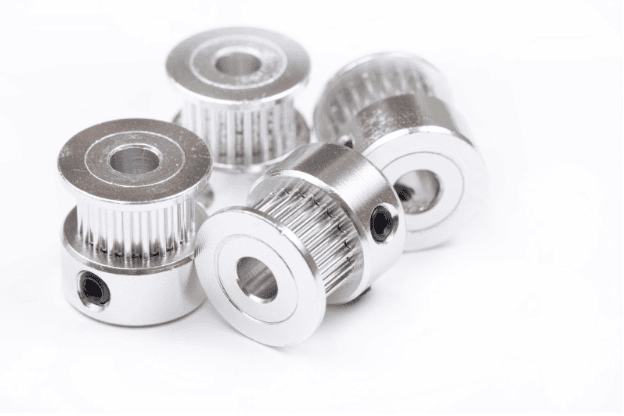

- Automotive: Producing engine parts, gears, and custom prototypes.

- Medical: Creating surgical tools, prosthetics, and medical implants with biocompatible materials.

- Electronics: Fabricating enclosures, circuit boards, and heat sinks.

- Consumer Goods: Designing custom furniture, jewelry, and home appliances.

No matter the industry, CNC machining enables innovation by making complex designs achievable and cost-effective.

Features

What sets CNC machining apart from other manufacturing methods? Here are some standout features:

- Automation: CNC machines require minimal human intervention, reducing the risk of errors and streamlining production.

- Scalability: Whether producing a single prototype or thousands of units, CNC machines can scale to meet demand.

- Versatility: From soft plastics to hard metals, CNC machines can handle a wide range of materials.

- Integration: Modern CNC machines can integrate with other technologies, such as robotics and IoT, for advanced automation.

Explore the full range of cnc machining services at Apogee CNC →

CNC machining has transformed how industries create and innovate, offering unmatched precision, efficiency, and versatility. By learning the fundamentals, you’ll be equipped to understand its role in shaping the products and tools we rely on every day.

Ready to take the next step? Explore further resources or reach out to professionals to dive deeper into the world of CNC machining!