Choosing the Right CNC Machining Shop Near You

At first glance, many shops look the same, each one promising precision, speed, and reliability. But if you’ve ever been up against a tight deadline or dealt with parts that didn’t meet specifications, you know that not every shop delivers on those promises. Selecting the right CNC machining shops near me is essential to keeping […]

Multi-Axis Machining: A Practical Guide

Multi-axis machining enables the efficient and scalable production of precision parts that cannot be done with traditional methods. Traditional 3-axis CNC machines can only move in straight lines along three directions, which makes it hard to create certain shapes or reach some surfaces. Multi-axis machining solves this by adding new types of movement—such as rotating […]

CNC Machining Tolerances: What Engineers Must Know

Tolerances define the level of precision needed. The tolerance achieved will affect how CNC machined parts fit, perform, and cost to produce. The level of precision can mean the difference between a reliable component and one that fails to perform. Understanding CNC machining tolerances and which level is right for your part, is essential to making […]

Learn CNC Machining

What is the backbone of the manufacturing space? Great question! CNC manufacturing. That car you drive, the phone you use, the aircraft taking you to new places, and the life-saving medical equipment owes its thanks to CNC manufacturing. CNC machining doesn’t just make parts; it builds the future. From aerospace and healthcare this process […]

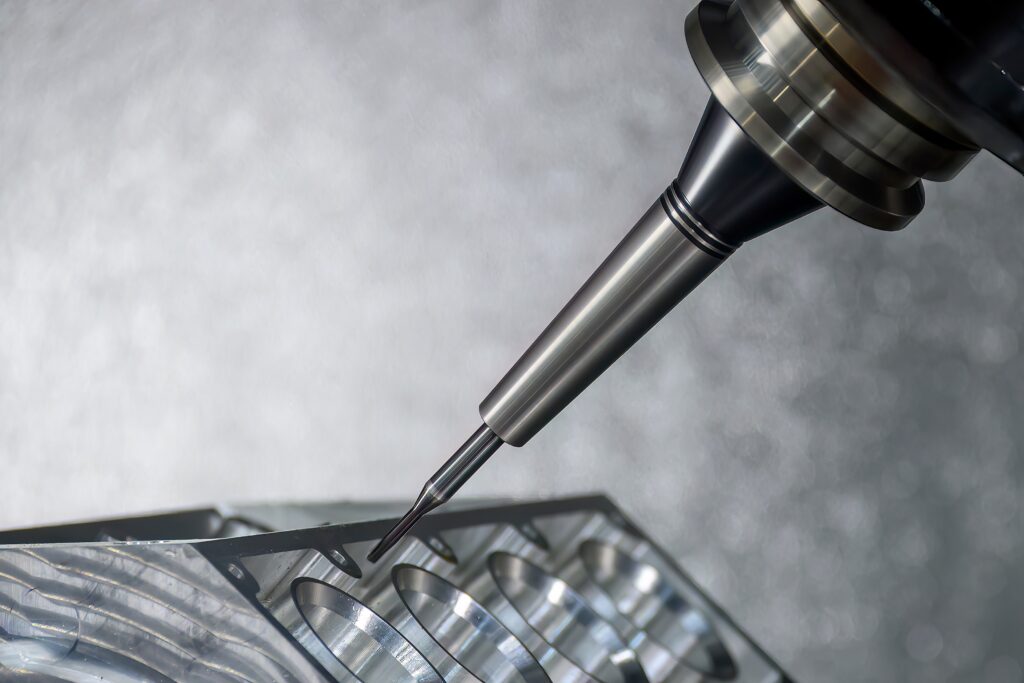

The Benefits of 5-Axis Milling

In precision manufacturing, 5-axis milling has changed the future of machining. This advanced technology allows manufacturers to machine complex parts with near exact precision, achieving tolerances as tight as +/-0.00001 inches on critical features. What is 5-Axis Milling? 5-axis milling refers to the use of CNC machines that move along five different axes: […]